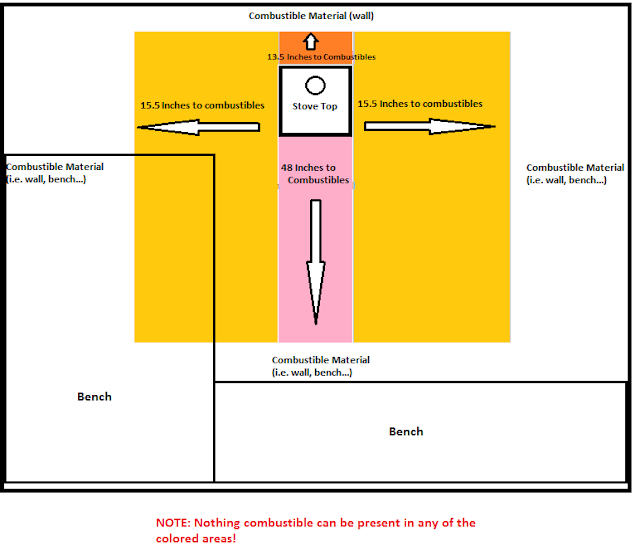

Up next we needed to build the sauna benches for the hot room. The bench layout in the room was constrained by the restrictions on clearances to combustibles imposed by the stove. The layout we had decided on was L-shape benches having a short bench run parallel to the wall opposite the stove, and a long bench running on the perpendicular wall to the right of the stove.

Next, we had to decide on the widths and heights of our benches. There are suggestions online, but, we decided it would be a subjective processes for us. For the height of our benches, we made our decision by estimating our average heights and decided on the bench being such that we could be sitting as high as possible without even the tallest guys hitting their head on the ceiling. I think the final height of top of the bench support ended up being 38 inches from the floor. Next, we needed to decide on the width of the bench. Same thing there—we measured an average from the back to the knees of the guys that’d use the sauna and came up with an 18” bench frame followed by about a 1” face piece. So now we had a rough idea of what we were doing.

Now, I needed to research which wood to use for the tops of our benches. I knew the bench frame would be done with Pressure Treated wood to save money. However, for the top bench finish, I had some choices. Obviously, cedar is a valid choice—but expensive and not sold everywhere. One note here, you need to use “clear”, “grade A”, “finishing” wood so there’s no splinters. Some popular woods are Poplar, Aspen, Birch. You can’t use pine or pine variants, they seep sap (seep sap, seep sap….). My decision came down to price, and the ease of purchase/availability. I chose Aspen. It’s a bright white wood without any significant smell. Not my first choice, but I decided I’ll redo it once I play and win the lottery.

With the Aspen bought ($200+), it was time to frame. We decided that the short bench would be the easiest since it didn’t require supports below it—only on the back and the 2 side walls. We had previously marked off the studs on the walls of the hot room, over cedar, where the benches would go. We now cut our Pressure Treated pieces to the lengths we wanted and installed them on the long wall and the short wall of where the benches will go. These will support the back of each bench. We secured them with 3 inch screws, two per stud, pre-drilling and screwing in to the studs at each marked location. We also cut a 2x4, the width of the bench and secured it to the opposite wall giving us the third of our three supports. Once we build the bench, it will simply rest on top of the three, 1.5 inch wide supports of the walls.

To build the bench we worked on a table outside of the building giving us plenty of space. We cut two Pressure Treated 2x4s the width of our hot room (minus .25 inch to be able to rotate the bench) for the long side of the bench, and 2 more that would be 18 inches, minus 1.5 + 1.5 to for the short side of the frame (the width of the bench). We secured all 4 sides in a rectangle shape by pre-drilling and using 3 inch screws. It’s OK to have the screw tops exposed, no need to sink them yet. They will be covered by Aspen, so no one will ever get burned on them.

|

| Framing a sauna bench from pressure treated 2x4s. |

With a basic frame complete, we took it in to the hot room to test fit. We placed it over our supports at the walls. It fit and seemed to be good.

REMEMBER— build the frame about a quarter inch shorter than the distance between the two opposite walls so that you can maneuver the bench without getting it stuck on the wall. You will need to be able to remove benches for cleaning and such.

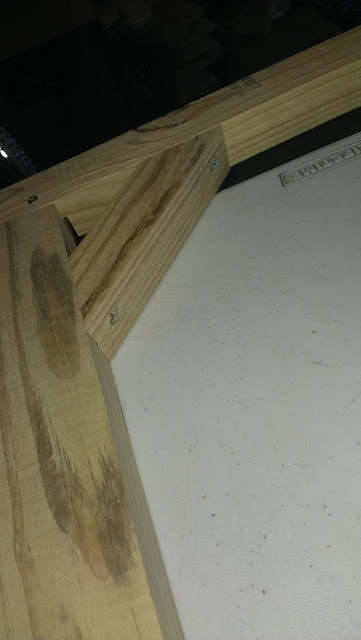

Next, we took the bench frame back out and added more dividers/supports between the long sides of the bench frame to make the bench rigid. We did this about every foot and a half. Now came the tricky part. You can’t have any screws exposed or they’ll get hot and burn people. So the Aspen needs to be attached to the bench from underneath the bench frame. To do that, we split a few 2x4s in twos and attached them to our dividers flush with where the top would be in an L-corner fashion.

|

| Sauna bench framing with blocking and L-corners to attach the top boards from underneath. |

These 2x2s were attached with 2 screws on both opposite sides. We then measured and cut our Aspen and ran screws from underneath the bench frame, through the 2x2 strips we attached half way in to the Aspen making sure they didn’t come all the way through. As always, we pre-drilled the holes before putting in the screws. In order to keep the space between the Aspen boards consistent, we used scrap DuRock pieces to maintain a half inch gap. The last Aspen board was cut to the remaining width of the bench and nailed to the frame with brads at a slightly higher air pressure then needed to make sure they sunk in well. Remember, this board is at the back of the bench. With the final board in place, we had our first bench. We put it back on the supports in the hot room and tried sitting on it. It held all 3 of us big guys very well. The only piece that was left is to attach the Aspen piece to the façade of the bench.

|

| Bench top wood secured to the bench frame from underneath. |

|

| Side view of the assembled sauna bench. |

The first bench we put together, we decided that a 18 inch width would work. After using it for a week, we decided we wanted to build the next bench a bit wider—perhaps 20 inches. Also, the next bench would be a little more tricky because it required building support underneath it since it didn’t have parallel walls to rest on. There were several hurdles with this support. One, the floor is concave for draining in the place where the bench would be. Two, the bench needed to be tied in to the wall studs to be sturdy, not just the cedar.

To begin, we decided to use a treated 2x4, the length of the bench, that we would attach to the floor. So we cut one and laid it down. Then, we measured up to the height of our bench, 38 inches, and cut two pieces that would go perpendicular to the floor piece. We only did this for the two opposite sides of the floor piece. This is because we wanted the part that flexes in the middle to be fully attached to the floor so we get the accurate measurements before we made any cuts. With the 2 pieces cut, we pre-drilled and screwed them from the bottom of the floor plate on to the floor plate. We then laid the floor plate equal distance from the wall and attached it to the floor, using two 4 inch screws in one foot separations.

Next, we cut another piece of treated 2x4 that would be the top plate for our support structure. We put a level going from our top plate to the 2x4 support which we previously attached to the wall. The benches would sit on top of both supports. The level showed we were still alright. We then pre-drilled holes and attached the top plate to the 2 pieces on both sides of the standalone support.

From here on, things were a bit easier. First, going off the locations of the screws that attached the wall bench support to the wall, we could tell where the studs were (along with our previous markings). We would need to attach blocking right underneath that support so that we could secure our standalone bench support to the studs. We simply used about 12 inch long pieces of treated 2x4, going the long way down and screwed one to each of the studs.

Now that we had blocking to securely tie the bench support to, we needed to finish building the studs of the standalone bench support structure. The only trick to that was that the edge of each stud needed to line up flush with the edge of each of the blocking we installed on the wall. Once we got each stud flush, we pre-drilled and screwed it to the top plate leaving the bottom hang. We went through and installed the rest of the studs the same way. We then used small blocking to secure the bottoms of these studs to the bottom plate. We simply level each stud, attached the blocking to the bottom plate and attached the stud to the blocking.

[PHOTO COMING SOON]

Finally, we went back, cut 2x4 pieces to reach from the wall blocking to the studs and secured them to the wall blocking only. Afterwards, we build another bench the same way as the first one, and put it on top of our supports. Now we could finally secure our standalone support to the pieces connected to the wall blocking by getting it to cleanly lineup underneath the bench. That is what tied the standalone bench support structure to the studs of the wall and make the whole thing solid. Solid as can be!

With that—we had all the benches we needed for a comfortable sauna. We still have the bottom benches to finish, but, the hot room now is more usable than ever, and I’m proud.

|

| Standalone bench support secured to the blocking attached to wall studs. |

|

| Both top sauna benches complete. |